Tech-Driven Traceability in the Indian Poultry Industry

Meghana Mukherjee Salvi

Director, Glamac International Pvt. Ltd.

Author’s Bio

Meghana Mukherjee Salvi is a poet, writer and blogger. She likes to study the market, analyse the trends and talk about everything related to Economics. Bumping into a good book is her guilty pleasure. She is a bibliophile from Bombay living with her husband and exceptional inlaws.

She followed in her father’s footsteps to set foot in the pharmaceutical industry. Before being in the poultry industry, Meghana completed her graduation in Mathematics, followed by a master’s degree in economics.

Transparency is the buzzword of this decade. Many are interested in knowing their meat and where it comes from today. Consumers are highly aware of what they consume, from checking ingredient labels and analyzing nutritional charts to certifications and acquiring allergen awareness. As per a survey conducted by the National Chicken Council, Washington, nearly 50% of the survey respondents would consume more chicken if they knew the production process was sustainable. And supply chain traceability can ensure farm-to-fork clarity, thus increasing demand or profitability and fostering roust brand trust.

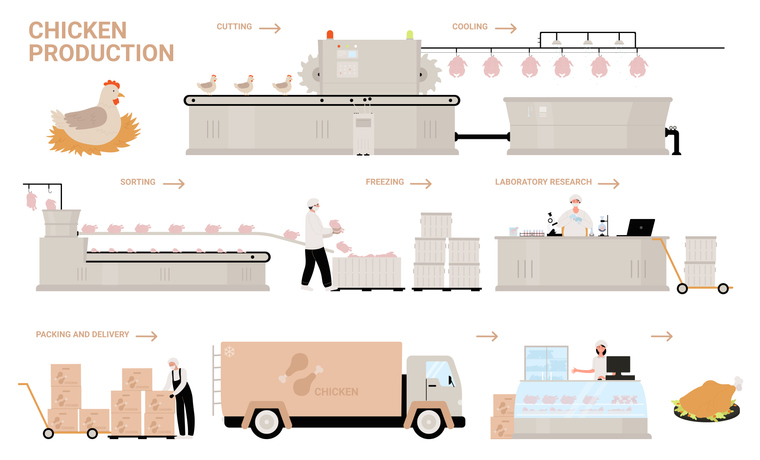

But what is farm-to-fork transparency? It is a concept wherein you can track a food product from where it was produced(farm) to the consumption point(fork). It will include information from production to processing to distribution and retail sale of the product for the poultry sector, its chicken meat and eggs. Accessible and transparent ideas about farming practices, processing methods, or storage and distribution aid in enhanced consumer satisfaction, loyalty, and easy identification of issues arising from a specific supply chain location.

Indian Poultry Sector at a Glance

The Indian poultry sector is growing at a rapid pace. The country is the third-largest broiler chicken producer and the second-largest egg producer globally. By 2050, India’s population is expected to skyrocket to approximately 167 crores. With a growing population, rising disposable incomes, changing food preferences, urbanization, government initiatives, increasing demand for processed meat and food, and advancements in poultry production, the sector is slated to grow at 8.1% CAGR from 2023 to 2028.

However, the game changer for the Indian poultry sector was the Integration Model. The business model includes consolidating multiple stages of poultry production like breeding, hatcheries, producing feed, poultry farming, and processing under one umbrella or entity.

Integration bolsters:

- Supply chain management – reduced logistical load and improved coordination.

- Cost reduction – Consolidation leads to bulk purchasing and centralized operations.

- Enhanced Biosecurity – Constant monitoring and centralized control minimizing disease outbreaks and promoting efficient risk mitigation strategies.

- Premium Quality: A standardized process will lead to effective implementation, ensuring consistent product quality.

Some key players like Godrej Agrovet, Venky’s, CP Foods, and Suguna, amongst multiple others, have built an all-encompassing supply chain practice and an exponential rise in product quality, genuinely transforming the face of the Indian Poultry Industry. These companies are adopting IoT, blockchain, AI, and data analytics to incorporate traceability further in their models.

Why Traceability?

Though you briefly understand why transparency is vital, especially for the poultry sector, peeling the layers and grasping the bigger picture is crucial. Let’s uncover the reasons behind the growing significance of Farm-to-fork transparency.

1. Food Safety and Quality

- Identification of contamination source in the meat’s production life cycle.

- 360-degree monitoring of the production process.

- Ensuring products meet quality and safety standards.

- Enabling swift and targeted recalls in case of challenging conditions.

2. Consumer Confidence and Brand Trust

- Transparency in products for consumer consumption.

- A positive demand outlook for neatly sourced and safe products.

- Satisfied consumers have higher chances of choosing a brand they trust.

3. Compliance and Regulation

- Traceability is now becoming a legal requirement to ensure compliance.

- Relevant certifications and adherence to compliance help meet international standards.

- An excellent International brand image increases exports.

- Assists in acquiring certifications like Kosher or organic.

Facilitating transparency in the poultry industry through technology

The key to achieving traceability is by traversing the road to technology. Automated systems, precise data, real-time monitoring of the entire poultry supply chain, and efficient record-keeping create a massive difference by enhancing operational efficiency, regulatory compliance, and food safety. Let’s look at poultry tech, which can be the language of 2024.

RFID & Barcode: RFID is a medium of identification. The technology uses radio frequencies to identify people/objects/flocks and transfer data. It reads information within a wireless device/tag without requiring any physical contact. Barcode readers use a beam of light to read the black-and-white printed code on the tag. This makes it easy to trace the product throughout its production life cycle.

Blockchain: Blockchain technology is like an Impenetrable and secure digital diary of data points, each point carrying its unique digital ID called a decentralized identifier(DID). Each batch of flock or individual product can have its own DID carrying information about its origin, production methods, etc. Each stage of the poultry supply chain is stored in blockchain and cannot be edited or deleted. Since it is a decentralized computer network, all the parties in the supply chain can access the same information, reducing discrepancies. Also, payments can be automatically processed after the successful delivery of a batch.

Data Analytics: It is also playing a significant role in facilitating traceability. By analyzing data from various sources, it is possible to monitor and verify the production process. This aids in identifying potential issues before they become significant problems and enables producers to take corrective action quickly.

Real-time Tracking with IoT: Integrating the blockchain with Internet of Things (IoT) devices allows real-time tracking of poultry products. Sensors can monitor temperature, humidity, and other conditions, and this data is recorded on the blockchain, ensuring transparency and compliance with quality standards.

Feathered Success Story: Suguna’s Journey to Traceability

In India, there needs to be more transparency in the supply chain. Yet many key players have identified the scope of growth and efficiency by relying on technology. One such pioneer is Suguna Foods, which has adopted RFID technology to trace poultry products from farm to fork.

Suguna Foods has more than 35,000 poultry farmers spread across the country, making it one of the largest poultry companies in India. The company has implemented RFID tags on the birds’ legs, which can be scanned at various stages of the production process, including hatchery, feed mill, farm, processing plant, and cold storage.

The data collected through these tags is then uploaded to a centralized database, which can be accessed by stakeholders such as farmers, veterinarians, and customers. This data includes information about the bird’s age, breed, feed, and medication, making tracing the product’s origin easier and ensuring quality and safety.

By implementing traceability solutions, Suguna Foods has established a strong relationship of trust with its customers. The company has also improved its operational efficiency, reduced waste, and increased profitability.

The Way Forward

The poultry industry has witnessed enormous transformation in the last few decades. Like the industry, technology, too, has been at the forefront of change and upgradation. It has prompted the push for increasing transparency across sectors not just limited to poultry. Blockchain, IoT, AI, and data will be critical in aligning the industry with future needs. It can ensure food safety and quality and increase consumer confidence and brand trust, paving the way for a safer and more sustainable future.

Hence, it is imperative that feed millers, farmers, integrators, animal nutrition companies, veterinarians, and consumers, who form the pillars of the industry, should embrace technology that promotes sustainability and transparency for a bigger, better, and healthier tomorrow.