Poultry Processing for a Profitable Broiler Business- India Perspective

Dr. Narahari, Project Consultant – Meat and Poultry, Processing and Meat Retail at NH ProPOWER Consultancy Services, Bengaluru, Karnataka

Dr Narahari a seasoned professional in the space of Meat and Poultry processing industry in India and has spent over 32 years working with reputed organizations in India and Middle east and held Middle and Senior positions. Graduated from Bangalore veterinary college during the year 1989 and completed PG diploma in Animal Husbandry from ITCPH, Philippines under Netherlands fellowship programme. His organization NH ProPOWER Consultancy services, Bangalore offers end to end solutions for Meat and Poultry processing, Further processing, Retailing and QSRs, currently doing projects in India, Middle East and Africa.

For more information contact: drnarahari@nhpropower.com Mobile: 9663376040

Introduction

The Indian broiler poultry industry, like the global industry, relies on innovations in the entire value chain of the broiler business. Unfortunately, the poultry processing sector faces innovation gaps crucial for ensuring the production of safe and hygienic chicken products to the general public from farm to table. The broiler industry in India has witnessed remarkable growth and transformation over the past few decades, positioning itself as a vital component of the country’s food production and economic landscape. The broiler industry is projected to contribute INR 1.5 lakh crores to the Indian economy. India ranked fourth in poultry meat production and second in egg production worldwide. As per the latest report by the Department of Animal Husbandry and Dairying (DADF), chicken meat accounts for an estimated 6.37 million tons, or 60 percent of total meat production, and is increasing at 6.86 percent annually. The substantial increase in production can be attributable to favorable climatic conditions and geographical diversity, which enable continuous production throughout the year. The demand for chicken products in India, especially broiler meat, is rising and fueling the industry’s growth and modernization. Recognizing the need and potential, the Indian government actively promoted expanding broiler industry by implementing several policy measures and helped to enhance competitiveness and sustainability of poultry farming operations. Still, the broiler industry in India holds immense potential for further expansion and diversification, driven by favorable market dynamics and evolving consumer preferences. Hence, by prioritizing innovation, sustainability, and inclusivity, the sector can sustain its success and significantly contribute to the nation’s animal husbandry, food security, and economic prosperity.

Breaking Down the Numbers: Why Poultry is the Fastest Growing Agro Industry

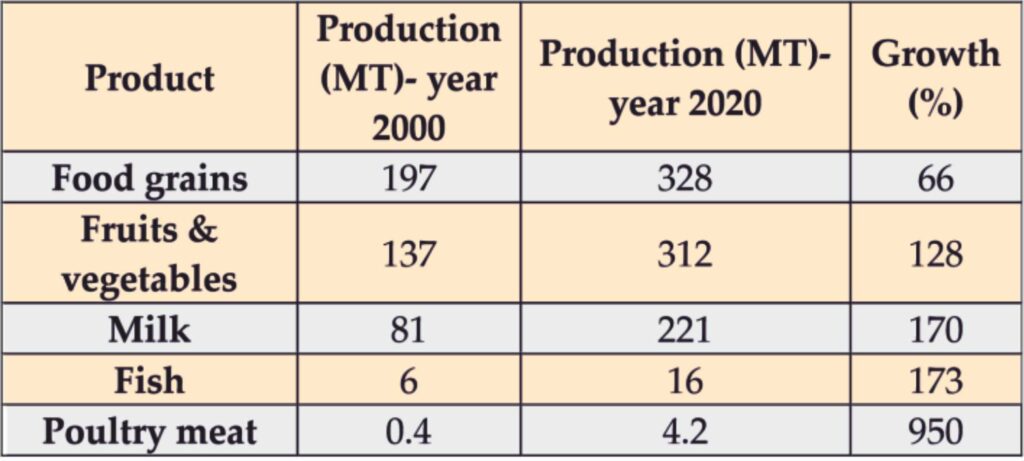

Agro-industries, including fisheries, poultry, horticulture, and dairy, are integral components of India’s agricultural landscape. In recent years, the poultry industry stands out for its rapid expansion and impressive scalability. Recent data indicates that there has been a growth of 66% in grain, 128% in fruits and vegetables, 170% in milk, and 173% in fish over the past two decades. Amazingly, in the same period, the growth in poultry meat production has surged by a staggering 950%.

Table 1. Data showing poultry production in comparison to other agricultural products

Source: World Bank Database, Ministry of Agriculture and Farmers Welfare, Basic Animal Husbandry Statistic, Horticulture Board of India.

The data show a remarkable growth compared to other food products and this growth is driven by factors such as changing dietary preferences, population growth, and economic development. Also, ease in poultry industry’s adaptability, efficiency, and scalability have positioned it as a key player in food production. However, after a record increase in production, it’s time to redirect attention towards poultry processing to satisfy the current generation’s desire for superior products. Moreover, poultry meat consumption per capita is expected to rise from 5.3 kg in 2022 to 9.1 kg in 2030 ‘ . Therefore, to cater to the needs of future demand, product type, and consumer preferences, one needs to scale up the poultry processing industry.

Sow, Grow, Reap: Healthy investment proposition in Value Chain Infrastructure Investment

The agricultural sector of India offers a highly attractive prospect for investment in the value chain infrastructure of poultry, covering poultry processing. In tandem with a growing urban population and urbanization, the demand for poultry products has increased steadily. Yet, the industry sector faces challenges in terms of efficacy, standards of hygiene, and distribution infrastructure. The “Sow” phase represents the foundational aspect of poultry farming and processing. With a population exceeding 1.43 billion, India presents a vast market for poultry products, including eggs and broiler meat. Specifically, broiler farms and processing plants could create up to 55% investment opportunity initially. As poultry production and processing advances to the “Grow” stage, opportunities for value addition and diversification become increasingly apparent. For instance, integrated poultry farming models, incorporating hatcheries, feed mills, and processing facilities, enable stakeholders to capture added value along the supply chain.

The “Grow” stage will be supported by a healthy investment proposition in the value chain of poultry infrastructure in India, given the current state of consumption trends, the imperative for modernization, and the need to enhance efficiency in order to meet the demands. The strategic utilization of these elements, investors can capitalize on the growth opportunities and make a positive contribution to the expansion of a sustainable and resilient poultry industry. Finally, “Reap” the opportunities for vertical integration or strategic alliances, where stakeholders can expect to obtain significant returns on their investments in the Indian poultry sector. The coming decade so will provide plenty of opportunity for the sector to realize the returns on investment.

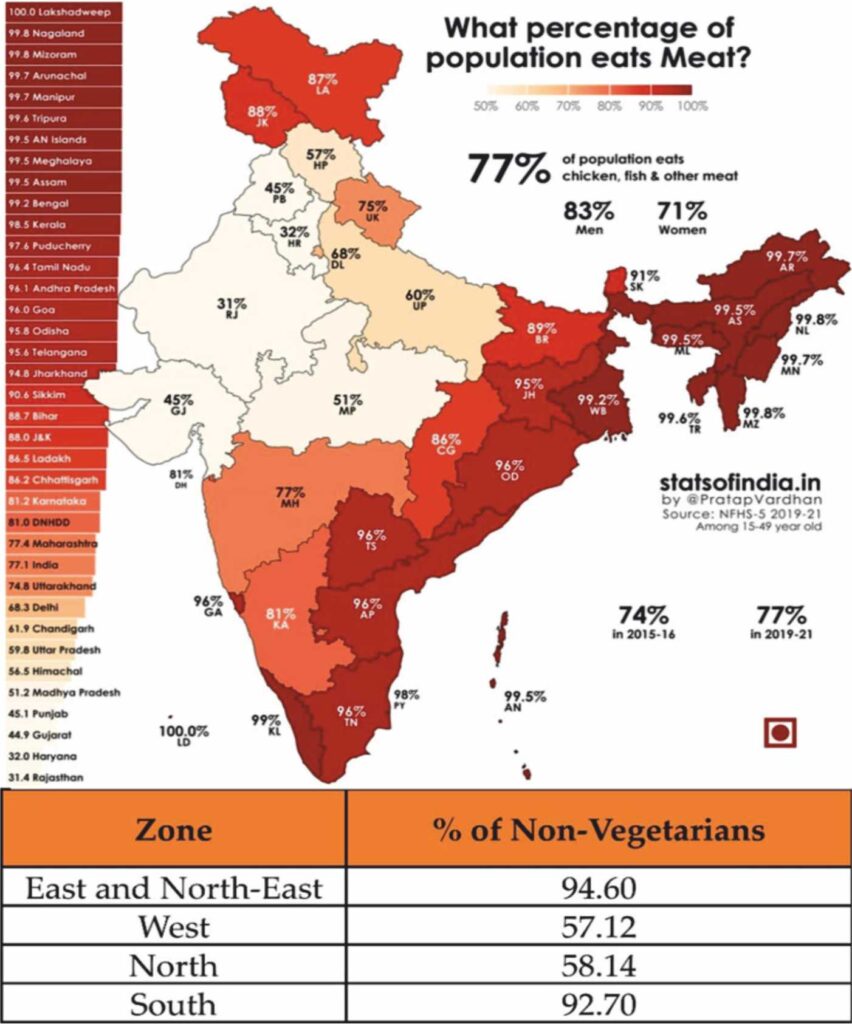

Figure 1. Pictorial description on meat eating population in India.

The data indicate the potential growth for chicken eating population in India.

Poultry processing and its influence on circular economy

The poultry processing industry in India is of significant importance in influencing the circular economy structure, as it offers a sustainable approach for utilizing resources, managing waste, and promoting economic development. As the poultry industry is expected to expand, driven by rising demand for poultry products, it is essential to understand the impact that poultry processing has on the circular economy. One of the key aspects of poultry processing lies in its utilization of by-products and waste streams. Poultry processing plants generate significant quantities of by-products such as feathers (7.5%)5%), heads (2.75%) (, blood (2.6%), feet (3.75%), gizzards, intestines, and glands, which, if managed effectively, can contribute to a circular economy model. These by-products can be transformed into value-added goods, such as animal feed, fertilizers, or bioenergy with anaerobic digestion, which helps minimize waste generation, reduce environmental impact, and create additional revenue streams. For instance, the gasification of poultry wastes could generate enough heat (up to 4.15 MJ/Nm3) that is sufficient to maintain the energy needs of poultry sheds. This allows the farm to switch from fossil fuels to a local renewable resource. This strategy can generate significant additional revenue through the sale of biochar by-products (INR 20000/ton) while circumventing disposal expenses of INR 3000/ton . Likewise, multiple strategies such as anaerobic digestion, pyrolysis, hydrolysis, enzymatic treatment, and others play a substantial role in augmenting revenue generation and reducing waste production in the poultry processing industry.

Moreover, poultry processing is crucial in generating employment opportunities and promoting economic growth, particularly in rural regions. The development of processing facilities not only generates direct employment in processing operations but also encourages ancillary businesses such as transportation, packaging, and equipment production. Thus, by adopting sustainable practices and utilizing innovative technologies, the poultry processing business can exemplify circularity, highlighting the potential to achieve environmental stewardship and economic prosperity.

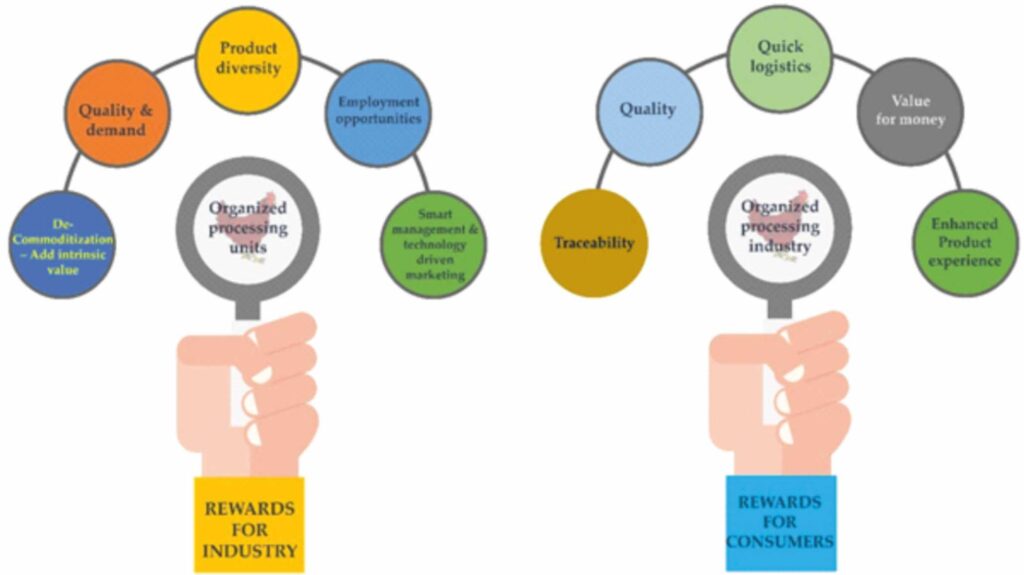

Rewards for industry from the organized processing

Organized poultry processing offers multiple advantages for the poultry industry, including enhanced market competitiveness, increased operational efficiency, and improved sustainability. Organized poultry processing operations significantly influence the optimization of the complete poultry value chain, thus offering the industry numerous advantages. Specifically, organized poultry processing plays a crucial role in de-commoditization, fostering sustainable growth, operational efficiency, market competitiveness, and ensures year-round predictability of business operations irrespective of seasonal variations. Additionally, it supports generating employment opportunities, aids authorities in monitoring the production line for improved management and contributes to marketing strategies led by technology and digitalization.

Rewards for consumers from the organized processing industry

The organized poultry processing industry provides consumers with a range of benefits, including convenience, variety, improved quality, and food safety. In light of consumers’ growing perception regarding the products they buy, organized poultry processing facilities are in an exceptional position to satisfy and surpass their expectations, delivering tangible benefits. Ideally, well organized industry provides traceability of the product, quality, quick logistics, value for money, and enhanced product experience prior to purchase. These added benefits redefine the perception on the poultry products and their quality. Also, consumers sense that organized poultry processing places a higher value on them, as it has the potential to offer a wide range of products that appeal to the majority of society.

Figure 2. Potential rewards for industry and consumers from the organized poultry processing

Current challenges in India’s broiler industry

Current challenges in India’s broiler industry include unexpected production, biosecurity lapses, workforce issues, waste disposal issues, and pollution. Besides inadequate infrastructure, lack of cold chain infrastructure, and market volatility all disrupt the development of the industry in India. Furthermore, these obstacles threaten profitability and sustainability, demanding stakeholders to work together to effectively tackle them and ensure a resilient and thriving broiler sector in India. For instance, to manage unexpected production, poultry processing capacities can be expanded by extending operational hours or investing in improved storage capacities. In this specific issue, The ability to adapt and devise strategic plans are critical factors in effectively managing variations in broiler production volumes. Next, it is crucial to strictly follow stringent biosecurity measures to address biosecurity lapses in the broiler business. This involves implementing controlled access measures, disinfection protocols, and strict hygiene practices to avoid the entrance and transmission of infections. Conducting regular training and awareness programs for farm workers is crucial to ensure adherence to biosecurity protocols. Moreover, employees at the processing plant have a crucial role in managing the challenges that develop. Investing in training and skill development programs is critical in improving the knowledge and competency of poultry farm and processing employees. Competitive wages, benefits, and a safe working environment can help attract and retain skilled labor in the broiler industry. Collectively, addressing these challenges requires a holistic approach that integrates challenges and provides solutions collaboratively. The collaboration of industry stakeholders, regulatory bodies, and research institutes is essential for developing and implementing broad solutions that safeguard the long-term viability and sustainability of the broiler industry.

Navigating the volatility in the broiler and processing business

Navigating the volatility in India’s broiler industry, one must adopt a multifaceted approach involving strategic planning, risk management, and agility in response to market dynamics. A crucial approach is diversifying product offerings and markets to decrease dependence. Also, expanding into value-added products or exploring export opportunities helps navigate difficult times. Occasionally, these measures leave a permanent mark as a solution for future growth. Furthermore, it is crucial to acknowledge the significance of adaptable production or processing methods that can swiftly accommodate fluctuations in supply and demand. Optimizing production or processing schedules and implementing robust supply chain management are essential to mitigate the impact of volatility in business. Apart from these, building robust relationships with customers, suppliers, and industry partners is essential to navigate the volatility effectively. These relationships offer valuable insights into the volatility by which one can understand risks, opportunities, and resource availability.

Conclusion

In conclusion, poultry processing for a sustainable broiler industry in India requires a concerted effort from all stakeholders. By embracing innovation, implementing robust biosecurity measures, investing in workforce development, and adopting sustainable waste management practices, the industry can overcome current challenges and pave the way for a more resilient and environmentally responsible future. India’s broiler business has the potential to thrive effortlessly in the future as to the expected demand for processed chicken products, provided that careful planning, cooperation, and adherence to established standards are implemented. The industry’s overall growth greatly contributes to food security and nutritional security. Poultry products fulfil the protein needs of today’s youth and help them achieve their aspirations in diverse spheres, including sports. Lastly, it campaigns for food production through environmental sustainability.

Figure 3. Adoption of multifaceted approach to navigate the market volatility in the broiler industry.