Poultry Processing and Solutions

MR. ALOK RAJ

PRINCIPAL CONSULTANT, APTEC

Mr. Alok Raj, the principal consultant at Aptec, unveils a career journey that commenced in 1977 with ICB Ltd, specializing in chemicals, bulk commodities, and mining. With a wealth of experience in agro-processing, oil-seeds, refining, and roles at Meyn Food Processing Technology, Mr. Alok Raj’s expertise culminates in pioneering insights. His 2009 venture, Aptec, stands as a testament to his prowess in diverse processing industries. His extensive knowledge base and hands-on experience continue to be instrumental in driving innovation and pragmatic solutions within the ever-evolving landscape of processing technologies.

Twice a year we at Aptec publish a status report on poultry processing in India. This report is available for anyone to download, read and reference, free of cost. Projecting for March 2025, we have the following scenario – 61 plants in the organised sector (i.e. plants with capacities of 1000 birds per hour or more) scattered in a highly skewed pattern across the Country. This scatter pattern does not represent location of chicken-consuming populations – it reflects other factors. The scatter needs to be uniform over the Country because that is exactly how chicken consumers are distributed. In another study we have also found that non-availability of properly processed and packed poultry is one factor that has kept consumption down to as low as 42% of its potential. You will find more details on all these claims on our website – https://aptec.in/

Fig. 1 : Location of organised sector poultry slaughterhouses in India, Industry Report uploaded in October 2023.

For a detailed study visit our website at https://aptec.in/Reports

Three questions ought to arise in the reader’s mind: how big is the poultry processing industry, what relationship it has with the wet market and what is its growth rate vis-à-vis farming output of broilers. We have conducted studies on these. By March 2025 the overall installed capacity of organized sector poultry processing will be 1,65,400 birds per hour (BPH) and together with smaller slaughterhouses processed poultry output in India will be approximately 15% of the total – the rest will come from the wet market. Between 2002 and March 2025 the growth of capacity addition in the organised poultry processing sector has been calculated by us at 12.25% CAGR. In contrast, the growth of broiler farming has hovered around 6% CAGR. Therefore, one can confidently conclude that over this period the wet market has been steadily diminishing, as it must, if India has to become a developed economy.

From the existing capacity of 1,65,400 BPH which constitutes a gross capacity expected by March 2025, processed poultry is expected to be performed efficiently and hygienically. Poultry coming from the wet-market route will constitute the balance (85% of the total) and is expected to be unhygienic, will be performed with waste of resources and be out of sync with poultry processing standards worldwide.

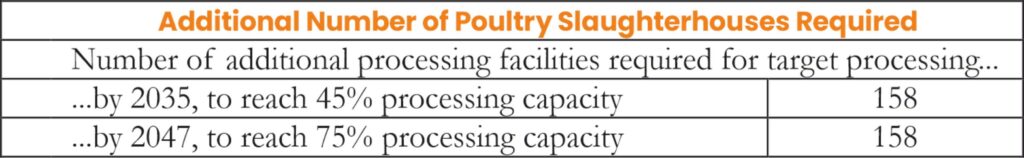

This 15% share must rise dramatically if this industry is to be brought at par with the developed world. We believe that when a country establishes capacity to process at least 70-80% of the number of broilers its farms produce, it can effectively shut down the wet-market. So, we may like to aim at 75% capacity processing by 2047 to reach that goal. Say 45% processing level by 2035 and 75% by 2047. To simplify our calculations, we will assume that neither the broiler farming sector nor the population nor the per capita consumption of chicken meat show any growth over these periods.

Using data available with us, we have calculated the additional number of poultry processing facilities of today’s average size that must be set up to reach these targets. The figures are:

Unfortunately, there simply are not enough suitable plant sites in India for so many poultry slaughterhouses.

How do we make such a claim? Because we have helped design and build nearly 50% of poultry processing capacity in India over the past quarter century, we have found identification of suitable land the most daunting part of the exercise. Our solution to this problem is in two parts – the first part requires investors in this industry to take the lead and the second part requires collective effort by industry and government.

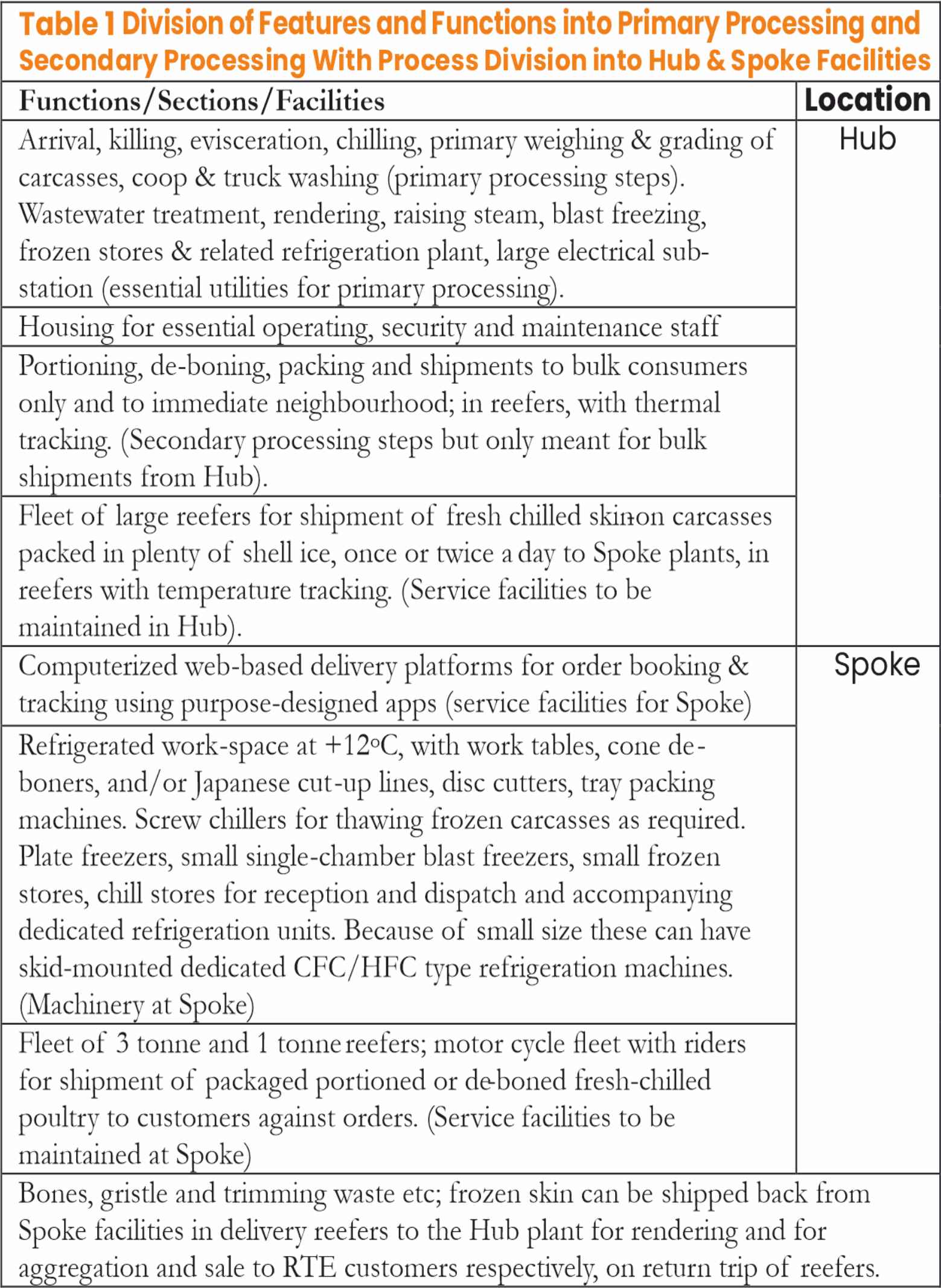

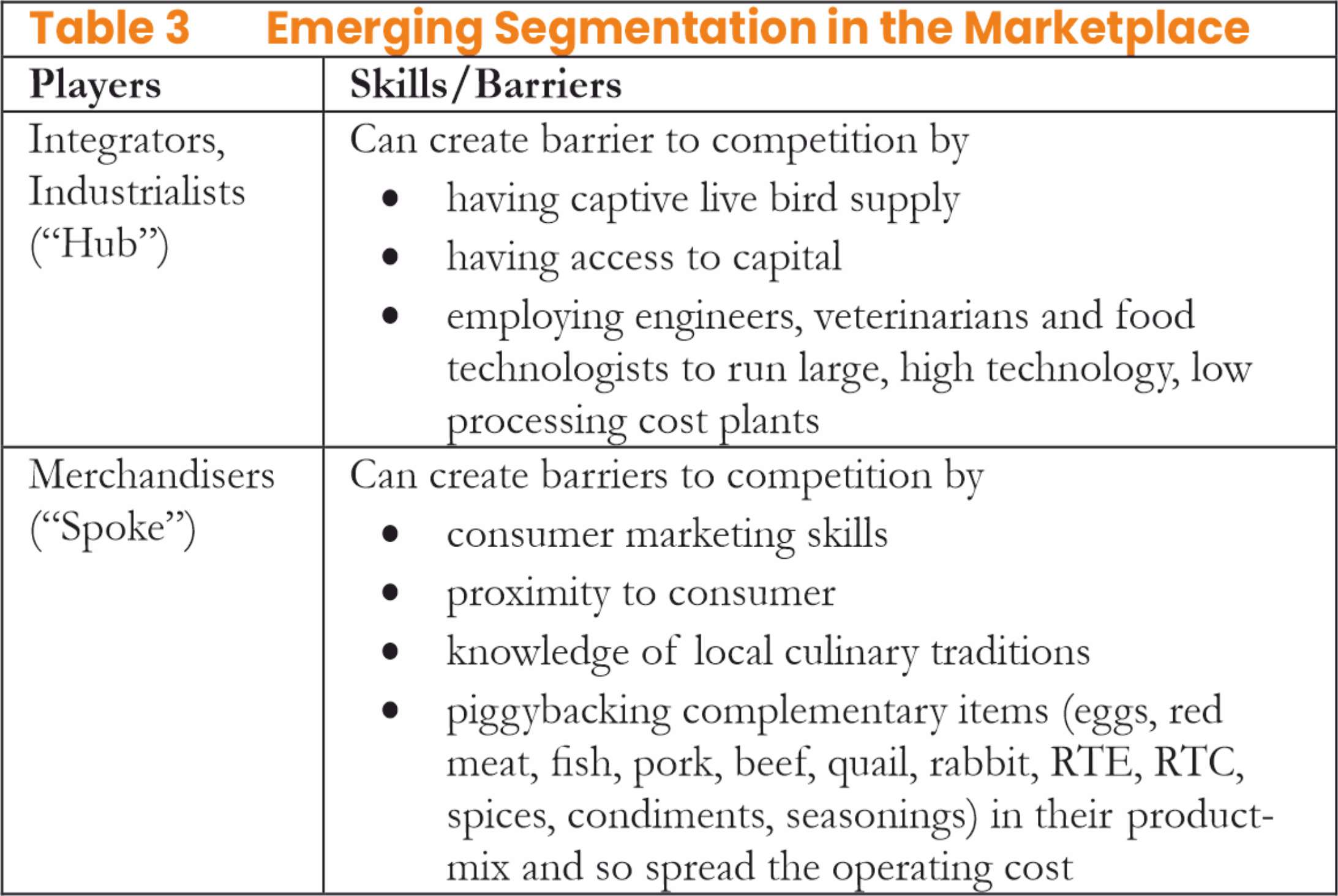

We spoke of the principal problem challenging growth of poultry processing capacity in India, namely the unavailability of suitable sites for plants with the present average capacity of 2710 birds per hour (BPH). We do have a solution to this problem. It requires a two-pronged strategy. The first is based on a proper understanding of the process itself, based on which we can split or divide the processing activity into two stages, each of which can function at a separate location. We call this the Hub & Spoke Model of Poultry Processing.

The second strategy is an itemised scrutiny of each hurdle to the growth of this industry and suggest custom solutions. But this requires cooperation between industry and government. Let us take up the Hub & Spoke Model and while discussing it, we will have the opportunity to itemise these individual hurdles.

1. Split the Process and Plant – Use the Hub & Spoke Model

This model is based on a close examination of Nine features of the process listed and discussed below. Some of them emerge as hurdles while others appear to favour splitting the process into Hub and Spoke, these being two halves of the process, separated into convenient sections that may function independently at different locations.

Poultry processing produces whole or portioned chicken, with each being either blast-frozen for long term storage or fresh chilled for immediate consumption (within 4-5 days of processing if kept refrigerated). In the case of portioned chicken, the market has a long laundry-list of product specification starting from cuts and packing size to whether or not the portions have skin-on or are deskinned, whether marinated or not, and so on. It should be clear to us that there is no disadvantage in splitting the primary and secondary steps (identified in table 1) into two locations as Hubs and Spokes. In fact, there exist excellent reasons to split them.

Aptec developed this model during September 2020 and privately distributed a short note on it among poultry processing plant owners. Later, following an interview of this author conducted by Asian Poultry Magazine in October 2020, Aptec published a report on this model in the January 2021 issue of the Industry Report.

2. Intensity of Scale Economies

Poultry processing is highly scale sensitive. Machinery manufacturers now offer line speeds of up to 15,000 BPH. As you go up the capacity ladder, the specific processing cost per chicken falls significantly. And here we are, struggling at an average capacity of 2710 BPH in India! Imagine the scale economies the processing industry is losing! If only we could improve scale economies in processing, poultry meat could become cheaper across the board.

3.Capital Intensity

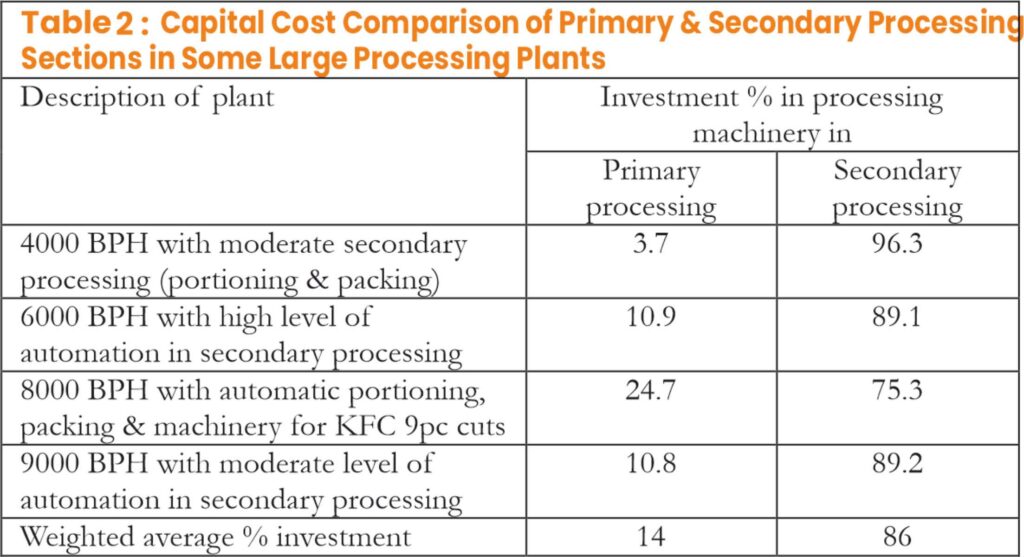

Poultry processing is also very capital intensive, requiring heavy investments. However, the bulk of the investment goes into primary processing. Table 2 shows this. Here you may note that the primary processing stage uses the bulk of the capital in processing equipment. Added to this is the need to invest large funds in refrigeration, waste-water treatment, rendering and electrical sub-station in primary processing, The capital needs of secondary processing is overall lower not only in processing machinery but also in connected load and refrigeration because much smaller capacities of these utilities are required. Besides, the secondary processing end needs neither rendering nor wastewater treatment nor complicated machinery.

4. Hunger for Resources

Poultry processing requires lots of water, generates need for a large effluent treatment facility and uses plenty of power for operation, mainly in refrigeration and rendering. But most of these resources are restricted to primary processing departments which include live bird hanging to whole carcass chilling with water and flake ice, freezing of carcasses and a primary weight-wise grading of carcasses. Blast freezing of whole carcasses can be undertaken at the Hub, helping to smoothen the mismatch between farm output and demand for chicken meat.

The Hub location could build large blast freezing capacities and frozen stores, thus qualifying them for MOFPI’s cold chain capital subsidy. This would enable them to benefit from periodic live bird price gluts. With adequate freezing and storage capacities, gluts would be progressively smoothened and poultry farming would become a low-risk activity, attracting more rural youth into contract farming.

5. Labour Requirements

A typical 6000 BPH plant needs from 300 to 400 workers if both primary and secondary processing stages are combined at one location. Of this, only 60-80 workers are required in primary processing – the rest being needed in secondary processing. Besides this, labour in primary processing must be very skilled while labour in secondary processing generally needs just one or two weeks of training. Because labour and staff number are small for Hub facilities, and such facilities need to be located in up-country areas, plant promoters may provide on-site housing and other facilities to them. Spokes may be built close to towns on industrial estate plots or in existing industrial sheds taken on lease. There are always some unused plots or sheds in industrial estates near most towns and cities. Labour requirement for Spokes may be sourced from among young unemployed youth resident in the nearby towns. This means that the staff needs no purpose-built housing and may use existing mass transit networks for commuting. Were the Hub & Spoke model to be implemented, manpower problems could be solved by extending the Skill-India initiative to cover this sector. By way of social engineering, a team could periodically pick promising young candidates from existing wet market and give them on-the-job training in existing modern poultry slaughterhouses, to be later absorbed in Hubs.

6. Work Schedule

In an integrated slaughterhouse the primary processing shift operation begins very early in the morning to match the arrival of live birds at the plant. Transport of birds generally occurs at night to save them from heat stress and reduce dead on arrival birds (DOA). The primary shift starts at around 0600 hrs and ends at say 1500 hrs whereas the secondary shift starts at 1100 hours and ends at 2000 hrs or goes beyond it, depending on workload. The secondary shift is staggered because of a technological factor called maturation. For maturation whole carcasses are rested for 4-5 hours at between -1 and +4oC to make poultry meat more tender and juicier. This results in a natural separation in the overall poultry processing activity. If maturation is allowed to happen during transport of carcasses from Hub to Spoke, we can effectively increase the shelf life of fresh-chilled poultry by 4-5 hours. This will happen because we will have merged two serial value-addition activities, namely maturation and transport to market within that single time-slot.

7. Rendering

Slaughtering waste is generated in primary processing and to protect the environment, reduce the spread of avian diseases and recover valuable protein from waste, one requires to have a rendering facility attached to each slaughterhouse. Secondary processing, on the other hand, generates practically no waste, except some bones when it is required to convert portions into bone-less meat. If de-boning is performed at Spoke, these bones can be rendered along with slaughter waste if they are delivered into the intake hopper of the rendering plant at the Hub.

8. Land

For treatment of wastewater, primary processing needs a large plot of land. Given the condition that treated wastewater must be used for irrigation, primary processing must occur in the midst of up-country agricultural crop or plantation land. Secondary processing has very limited need of land as it generates no waste-water stream. It can therefore conform to industrial estate standards and be located near towns, closer to consumption centres.

9. Inventory Management

In a large processing plant, the preoccupation of managers in primary and secondary processing is very different. The manager of primary processing handles veterinary, technical and machine maintenance issues while the manager of secondary processing grapples with logistical, scheduling and inventory management issues. No doubt, there are several common concerns like biosecurity, hygiene and workers’ safety, but the difference in their focus is important.

Secondary processing can produce a large number of product types or SKUs. These are distinguished, one from another, by the size of packing, whether frozen or chilled, whether mixed portions (curry-cuts) or only one type of portions in a pack, whether skin-on or skin-off, whether bone-in or bone-out, whether edible offal or prime chicken portions, whether bulk-packed for institutions or small packs for consumers, whether marinated or not and so on. So, the larger his operation and the farther he is from the consumer, the harder does the inventory management job of the manager become and from time to time he may get burdened with unsold inventory, which he must get rid of, by offering discounts.

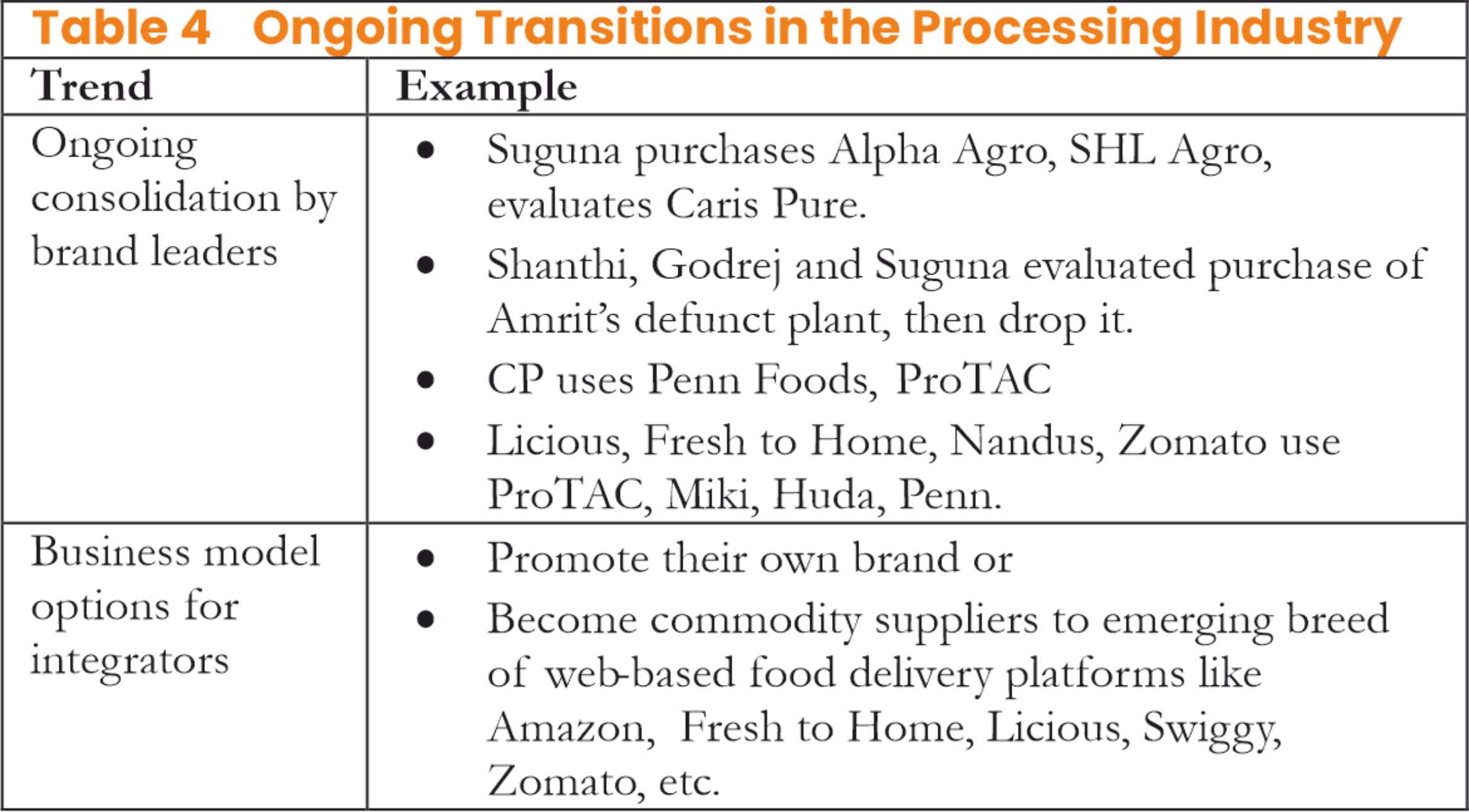

Emerging Market Conditions Suit the Hub & Spoke Model

In recent years a number of companies have sprung up as home-delivery outfits. From each centre they cater to a geographically small market which their delivery boys or small trucks can service directly. They hold an undifferentiated inventory of fresh-chilled whole carcasses which they source from existing poultry slaughterhouses and process them into the desired SKUs against orders received by mobile phones or over the internet. So, they do not have any dead inventory to carry.

As municipalities chased most of the wet-market vends out of cities and towns over the recent past, these operations went underground and become invisible. Some of them took a cue from the home-delivery outfits and climbed onto their band-wagon. In effect the municipal drive made the wet-market computer-savvy and their members set up web-based home-delivery platforms. Like the current phenomenon of cloud kitchens, we now have cloud-slaughterhouses as wet-market butchers no longer need to display the actual slaughter process. But this development fails in terms of product hygiene, biosecurity and sanitary disposal of processing waste. These clandestine operators continue to dump their processing waste onto landfills or into municipal drains.

If the processing industry sets up a sufficient number of Spoke units it may benefit from the home-delivery trend and together they may either improve processing conditions in these clandestine cloud slaughterhouses or cause them to shut down. The industry may also try promoting entrepreneurship among urban unemployed youth by including them in a franchise arrangement at Spoke establishments, just as reducing price volatility by Hubs may promote unemployed rural youth to take up contract farming.

For the processing industry to adopt this idea, large integrators should convert their existing plants into Hubs, operating large capacities to the tune of 12,000 BPH for 2 shifts, the better to utilise their assets. Simultaneously the industry should rapidly set up many Spoke facilities close to cities and towns. To sum up, by splitting the process into two steps, we contain pollution, better manage water and power requirements at fewer locations, where we can solve these issues more efficiently because the solutions themselves exhibit scale economies. Besides, by restricting pollution generation and abetment to fewer locations, better control and compliance may become feasible. The poultry processing industry can leverage recent market developments and adopt emerging business models to expand product distribution and encourage enterprise among youth.

Scale economies express how much more it costs to process one chicken is when it is performed in a plant running at 1000 BPH as compared to doing it in, say, a 6000 BPH plant. To obtain actual figures, download AptecApp from the Aptec website. This App allows you to choose from 5 different plant sizes, configure the product mix to your liking and it immediately generates the entire financial feasibility calculations. It also shows you how much a typical kilogram of marketable product costs to produce with your just-configured product mix and capacity settings. Maintaining the same product mix, switch to a different capacity choice and study the financials. You can read how much it costs to process at that capacity. This will illustrate the sensitivity of processing cost to scale of operation. Even within a single plant capacity setting you can choose a 20% over capacity or 20% under capacity operation and see the impact of specific processing cost.

A stock-keeping unit (SKU) is a scannable bar code, most often seen printed on product labels in a retail store. The label allows vendors to automatically track the movement of inventory. The SKU is composed of an alphanumeric combination of eight-or-so characters.