BAADER: Fostering Long-Term Relationships in Poultry Processing

Regardless of scale, poultry processors share the goal of advancing and expanding their businesses. Whether operating on a small scale or within a high-capacity processing facility, maximizing profits, and fostering growth are paramount. This underscores the importance of partnering with a processing equipment supplier capable of supporting sustainable, continuous growth and nurturing long-term relationships.

As a family-owned company with a century-long legacy, BAADER embodies a steadfast commitment to longevity, reliability, and enduring partnerships over short-term gains. Our core values serve as guiding principles, shaping our decision-making processes, and emphasizing the cultivation of enduring bonds with customers worldwide.

At BAADER, we take pride in offering scalable and adaptable solutions tailored to the unique challenges of each market and customer. Our focus remains steadfast on designing solutions that facilitate uninterrupted growth. With decades of global experience, we have curated a diverse portfolio capable of meeting local market demands while accommodating operations of all sizes.

From Farming to Poultry Processing

Transitioning from poultry farming to processing is a strategic move for business expansion. However, this step involves significant investment and requires acquiring specific processing knowledge. Partnering with BAADER can greatly facilitate this transition. New processors will benefit from comprehensive training in both processing and maintenance, drawing on BAADER’s extensive expertise.

Moreover, BAADER offers tailored solutions for startups and small-scale operations, such as our Compact Plant 396. This system is designed to fit within a shipping container, enabling easy installation and immediate commencement of processing. The equipment is equipped for automatic stunning, scalding, and picking, with evisceration processes conducted manually along the line. This setup is an excellent option for small-scale processors looking to take their first step towards automation, combining simplicity with efficiency in a compact solution. Complementing the Compact Plant 396, our product range includes chilling, cut-up, and packing equipment that can be seamlessly integrated as the processing business expands.

Delivering High-Speed Processing and ensuring Large-Scale Production

As a global leader in poultry processing, we are committed to continuous innovation, driving the development of cutting-edge technologies and delivering state-of-the-art processing facilities.

The Compact Plant is a stand-alone slaughtering and evisceration solution.

Our high-end solutions stand at the forefront of modernity and efficiency, enabling processors to automate operations from live bird catching at the farm to final dispatch.

Regardless of capacity, BAADER solutions are engineered to uphold reliability, flexibility, and quality assurance. Designed to accommodate diverse flock sizes, our equipment facilitates flexible processing, capable of meeting various market demands. This versatility empowers processors to cater to multiple markets seamlessly from a single processing line.

The BAADER Production Management Software optimizes processing efficiency by utilizing individual bird weight, count, and quality data to allocate each bird to the most suitable further process. This intelligent allocation ensures effective distribution of products, maximizing line utilization and meeting daily sales orders with precision.

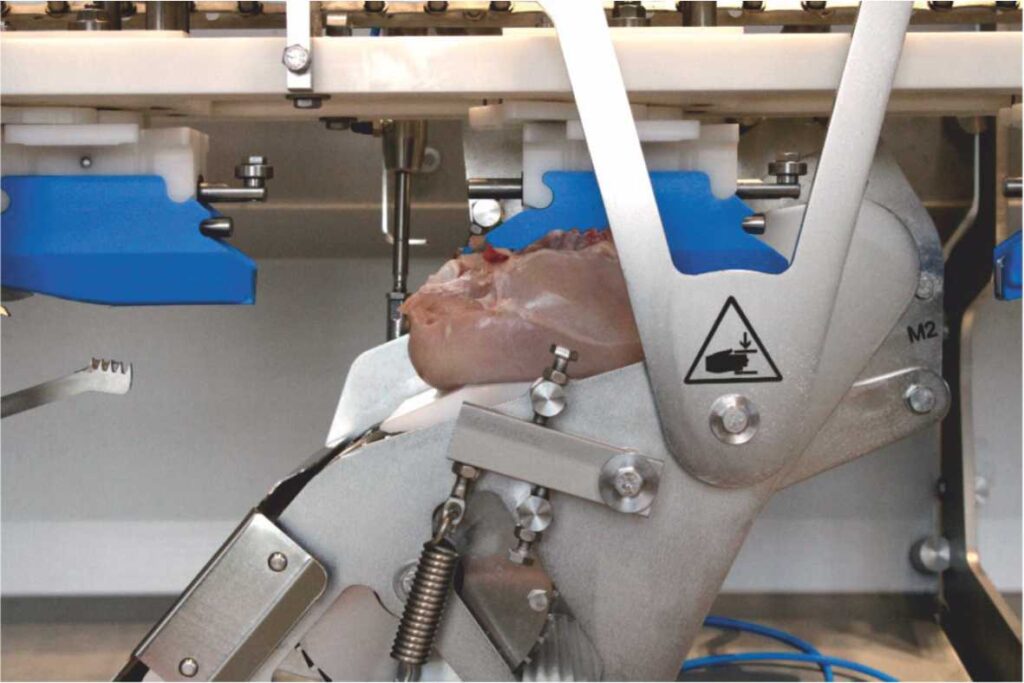

The BAADER evisceration line allows for processing a variety of different bird sizes.

Customized Automation Solutions

The level of automation is customizable for each processor’s unique needs. Our solutions cater to all degrees of automation, from live bird handling to evisceration, cut-up, deboning, grading, and packing. Collaborating closely with each processor, we tailor the optimal solution to ensure seamless integration and maximum efficiency.

Transitioning from manual to automated processes necessitates maintaining adaptability to the product being processed. High equipment adjustability is essential, and sophisticated intelligent product measuring, as exemplified in BAADER breast filleting solutions, plays a crucial role. With this technology, each breast cap or front half is measured, enabling automatic adjustment of cutting and scraping tools. This ensures consistently high product quality and yield performance.

Automating the filleting process dramatically reduces labour dependency while unlocking higher production capacities.